Global Standards Ensure Rigorous Testing Frameworks

Key international standards guide NEV environmental testing chambers:

ISO 16750-4: Defines temperature ranges (-40°C to 125°C) and humidity conditions (e.g., 85%RH at 25°C) for electrical components (e.g., motor controllers, on-board chargers).

UN R100: Requires electromagnetic compatibility (EMC) testing for battery systems under constant humidity (e.g., 50%RH at 25°C).

UL 1642: Specifies battery charge/discharge cycles under high-temperature humidity (85°C/85%RH) to assess thermal stability.

ISO 26262: Integrates environmental testing into functional safety validation to prevent component failures.

Scientific Protocols Simulate Extreme Scenarios

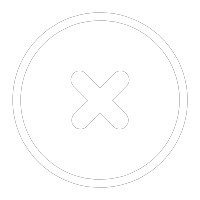

Climate test chamber of Critical tests include:

Temperature Cycling (ESS chamber) : Mimics seasonal or geographic extremes (e.g., rapid cycling from -40°C to 85°C at ≥5°C/min, or thermal shock (thermal shock chamber)between -30°C and 60°C with ≤10min transition time).

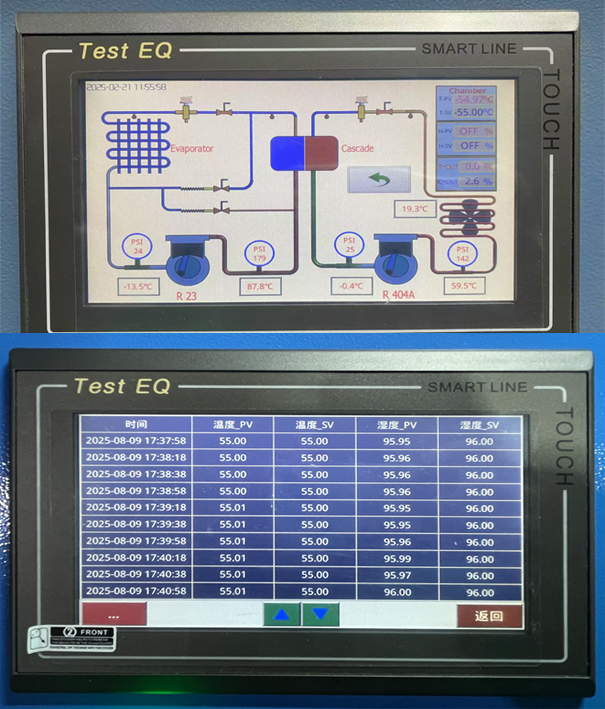

Constant Humidity Testing: Replicates humid climates (e.g., 85%RH at 25°C for 168 hours) to evaluate insulation, corrosion resistance, and sealing integrity.

Testing process: Pre-conditioning (24-hour stabilization at ambient conditions) → Programmed temperature/humidity cycles → Real-time parameter monitoring (voltage, current, temperature) → Compliance evaluation against safety and performance benchmarks.

Professional Services Elevate Product Quality

As a CNAS and CMA accredited laboratory, we offer advanced walk-in constant temperature and humidity chambers (-70°C to 180°C, 20%-98%RH humidity range) for whole-vehicle and large-component testing. Our expert team provides customized solutions aligned with regional standards (e.g., tropical vs. arid climate adaptations) and delivers internationally recognized reports.

Collaborating with industry leaders like Tesla, BYD, and CATL, we address challenges such as battery swelling under heat and low-temperature controller failures, enhancing market competitiveness.

Conclusion

Constant temperature and humidity testing acts as a "litmus test" for NEV environmental reliability, reducing failure risks in extreme conditions. Looking ahead, we will align with evolving standards (e.g., ISO 16750-4:2024 revision) to deliver efficient, high-precision testing services, driving the industry toward safer, more durable electric mobility.

Customize your environmental test chambers ,please feel free to contact with us online,thank you.