Pressure Accelleration aging test chamber -HAST

1 Scope

This International Standard provides a standard test procedure for the purpose of evaluating, in an accelerated manner, the resistance of small electrotechnical products, primarily nonhermetically sealed components, to the deteriorative effect of damp heat.

The test is not intended to evaluate external effects, such as corrosion and deformation.

2 General description

In this test, the specimen is subjected to very high levels of unsaturated damp heat for a relatively short period.

Electrical bias is usually applied.

Due to the very accelerated nature of the test, careful consideration must be given to the choice of test conditions, since this may have an important effect on the type of failure mode which could occur (see annex B).

The test provides three temperatures at a relative humidity of 85 %. The test severity is defined by the duration at one of the temperatures.

Care shall be taken not to reach the maximum rated temperature of the specimen and/or the critical temperature of any encapsulating materials. The glass transition temperature of a plastic is a typical example of a critical transition temperature.

In the case of plastic encapsulated components, degradation results from absorption of water-vapour by the plastic, and penetration of moisture along terminals.

3 Description of test apparatus

3.1 The test chamber The chamber shall be so constructed that:

a) it can produce the temperature and relative humidity given in table 1, and sustain the pressure values given in clause 4, note 3;

b) it is capable of providing controlled conditions of temperature, relative humidity and pressure during testing, and the ramp-up to, and ramp-down from, specified test conditions;

c) the temperature and humidity of the chamber can be monitored by means of sensing devices located in the working space, and/or other areas giving the same results (e.g. a steam generator).

NOTE-The direct measurement of relative humidity during this test is not possible with current techniques. Guidance on the determination of the relative humidity in the working space is given in annex C.

d) the enclosed atmosphere can be expelled from the chamber by the water-vapour prior to the commencement of testing;

e) condensed water is not allowed to fall on the specimen;

f) the materials used in the construction shall not cause any corrosion of the specimen, or degradation of the quality of the humidifying water (see clause D.2).

The temperature tolerance of t2 C is intended to take account of absolute errors in the measurement, fluctuations of the chamber temperature at any point, and variations between all points within the working space.

However, in order to maintain the relative humidity within the specified tolerance of t5 %, it is necessary to keep the difference between any two points in the working space (at any instant) within narrower limits.

The specified humidity tolerance will be exceeded if such temperature differences exceed 1.5 °C. It is also necessary to restrict the short-term temperature fluctuations due to cycling of the chamber heater to a similar value.

The specimen should not significantly impede the vapour flow.

Condensation shall not be allowed to form on the specimen at any time during the test.

3.2 The humidifying water

Distilled or deionised water shall be used. The water shall have a resistivity of not less than 0.5 MΩcm at 23 °C. The pH value shall be between 6,0 and 7,2 at 23 °C.

Before the water is placed in the humidifier, all internal parts of the chamber shall be cleaned. Guidance on cleaning is given in clause D.4.

4 Severities

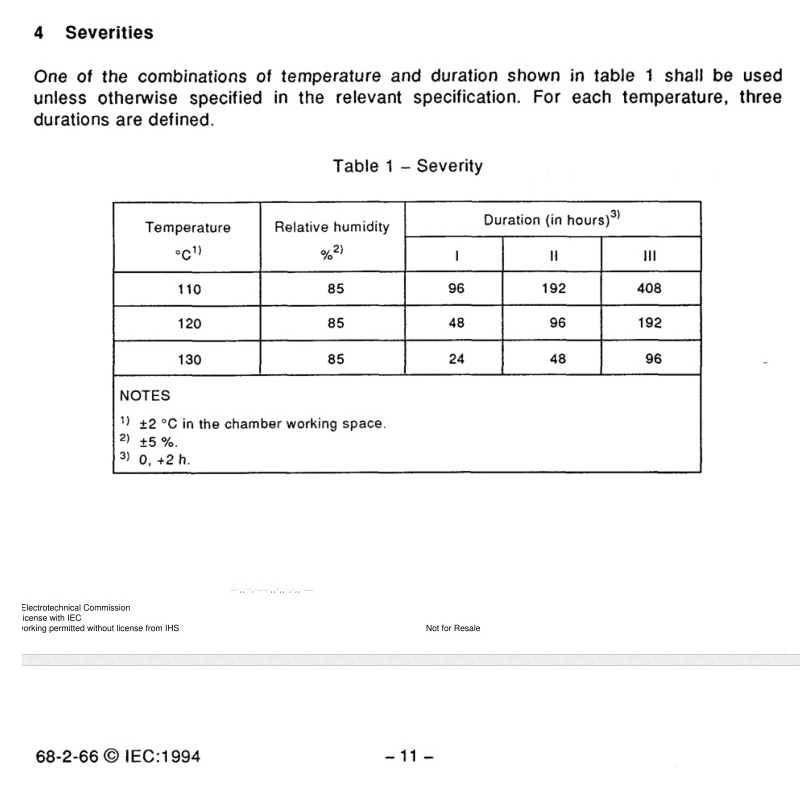

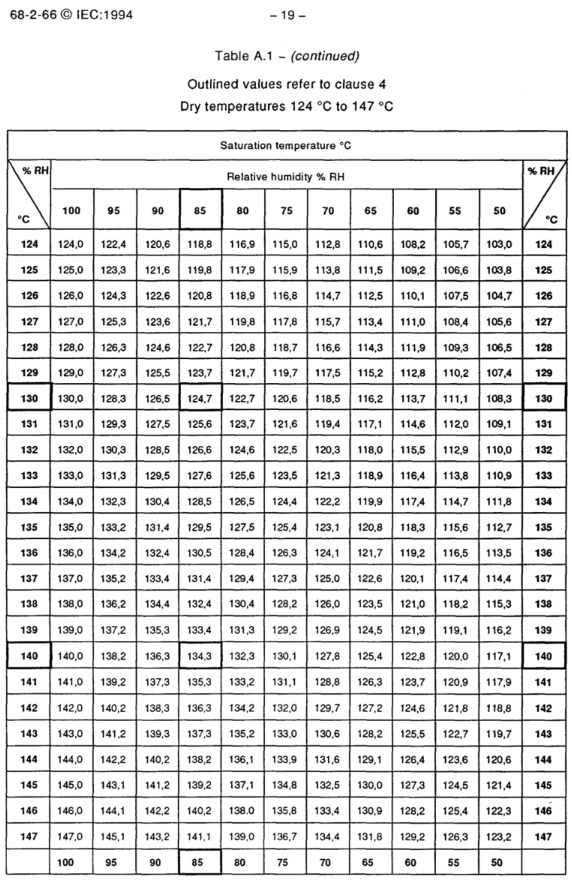

One of the combinations of temperature and duration shown in table 1 shall be used unless otherwise specified in the relevant specification. For each temperature, three durations are defined.

NOTES د

1 It is not recommended that a test should be restarted; however, if, at a given temperature it is required to subject the specimen to a longer duration than that given in column Ill of table 1, then the test shall be recommenced in accordance with the requirements of clause 6. The test shall be recommenced within 96 h of the end of the ramp-down period of the previous test.

During the interval between the tests, the specimen shall be held under standard atmospheric conditions for measurement and tests, unless otherwise specified in the relevant specification.

2 The durations given for testing at the specified conditions do not include the additional time required for the ramp-up and ramp-down period and the chamber cleaning and preparation time

3 The vapour pressures are approximately 0.12 MPa, 0.17 MPa and 0.23 MPa at 110 C 120 C and 130 °C respectively.

6 Testing

6.1 With the chamber and specimen at the laboratory conditions of temperature, pressure and humidity the specimen shall be installed in the working space in the chamber.

6.2 Positioning and mounting of the specimen The specimen shall not be subjected to radiant heat from the heaters or the chamber wall.

If required by the relevant specification, a specific mounting structure shall be used. The heat conductivity and the thermal capacity of the mounting fixtures shall be low so that for all practical purposes the specimen is thermally isolated.

Care shall be exercised in the choice of mounting structure and mounting fixture materials to minimize the effects of contamination and to minimize degradation due to corrosion and other mechanisms (see clause D.2).

6.3 Bias voltage

If required by the relevant specification, the specimen shall have a bias voltage applied during exposure. Guidance on the application of bias is given in annex D.

The bias voltage (or bias voltage cycle) shall be applied to the specimen when the temperature and the relative humidity have reached the stable state, and continue until the specimen is under recovery conditions.

6.4 The test cycle

6.4.1 The temperature of the chamber shall be raised to the appropriate value During this period enclosed atmosphere is expelled from the chamber by the water-vapour, and the temperature and the relative humidity shall not exceed the specified value. Condensed water is not allowed on the specimen at any time during the test cycle. Stabilization of temperature and humidity shall take place within 1,5 hours.

However, if stabilization takes longer than 1,5 hours the test requirements will be met if stabilization is achieved in not more than 3 h and the specified test duration is greater than 48 h.

6.4.2 The temperature and relative humidity shall be maintained within the prescribed limits for a duration as specified in the relevant specification. The test duration shall commence as soon as the conditions have stabilized.

6.4.3 At the end of the specified duration, the chamber pressure temperature and relative humidity shall be restored to standard atmospheric conditions for measurement and tests in not less than 1 h and not more than 4 h.

During this period, the temperature and the relative humidity shall not exceed the specified value. The conditions may be achieved by means of natural cooling.

If the pressure is reduced by release from the chamber, care shall be taken that the specimen is not subject to rapid depressurization. The pressure shall not fall below the laboratory pressure. The bias should normally be maintained during this period.

6.4.4 On completion of the cooling period, the specimen shall be subjected to the recovery procedure.

7 Intermediate measurements

The relevant specification may require electrical and/or mechanical checks during testing.

If it is required to make intermediate measurements, the relevant specification shall define the measurements and period(s) during testing after which they shall be carried out. The measurements shall not cause any change to the test conditions.

Measurements preceded by recovery which would require the removal of the specimen from the chamber are not permissible during testing.

Act now to enhance product reliability! Order HAST/PCT test chambers this month and enjoy free standard calibration service plus warranty on core components!

Submit inquiry for exclusive solutions: Click to fill in the requirements form | Email : kris@testeq.com

⚠️ The first 10 inquirers of today will receive an additional IEC 68-2-66 test guidebook!