Features:

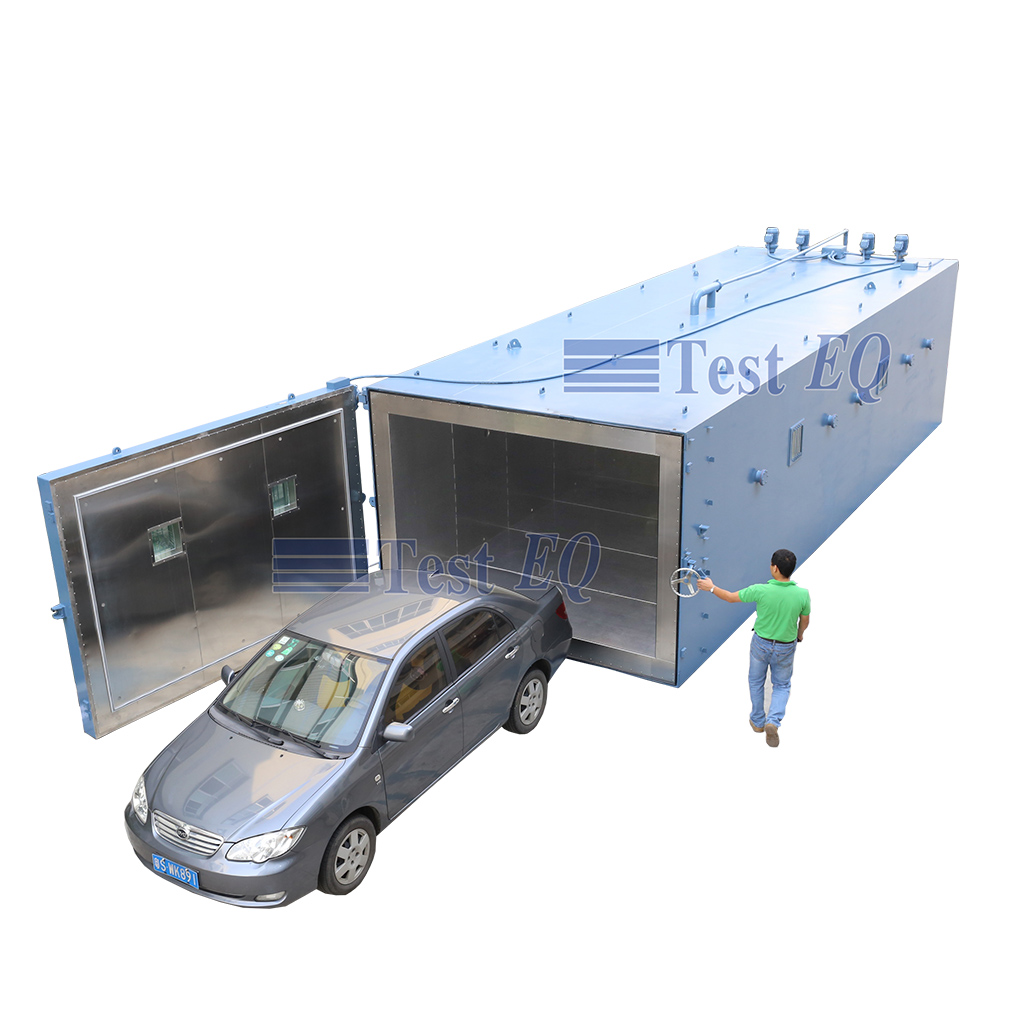

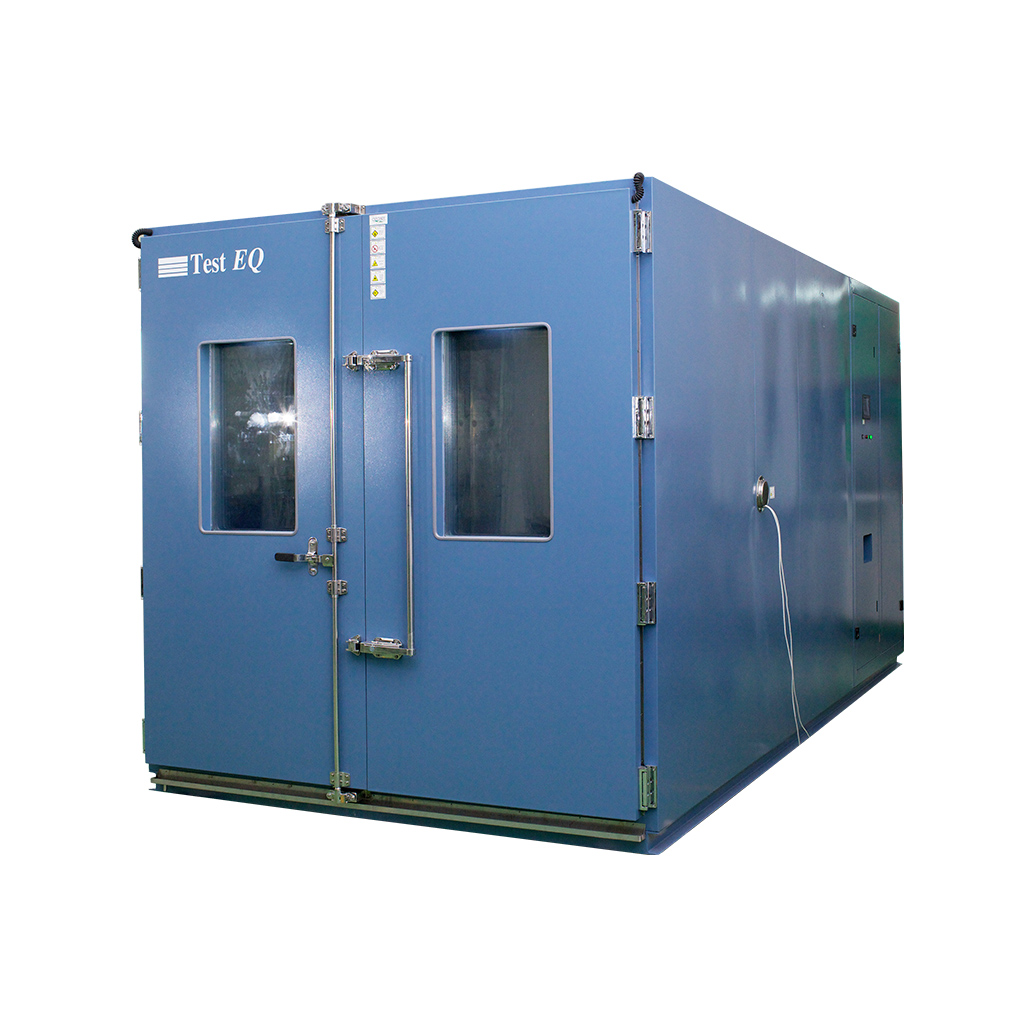

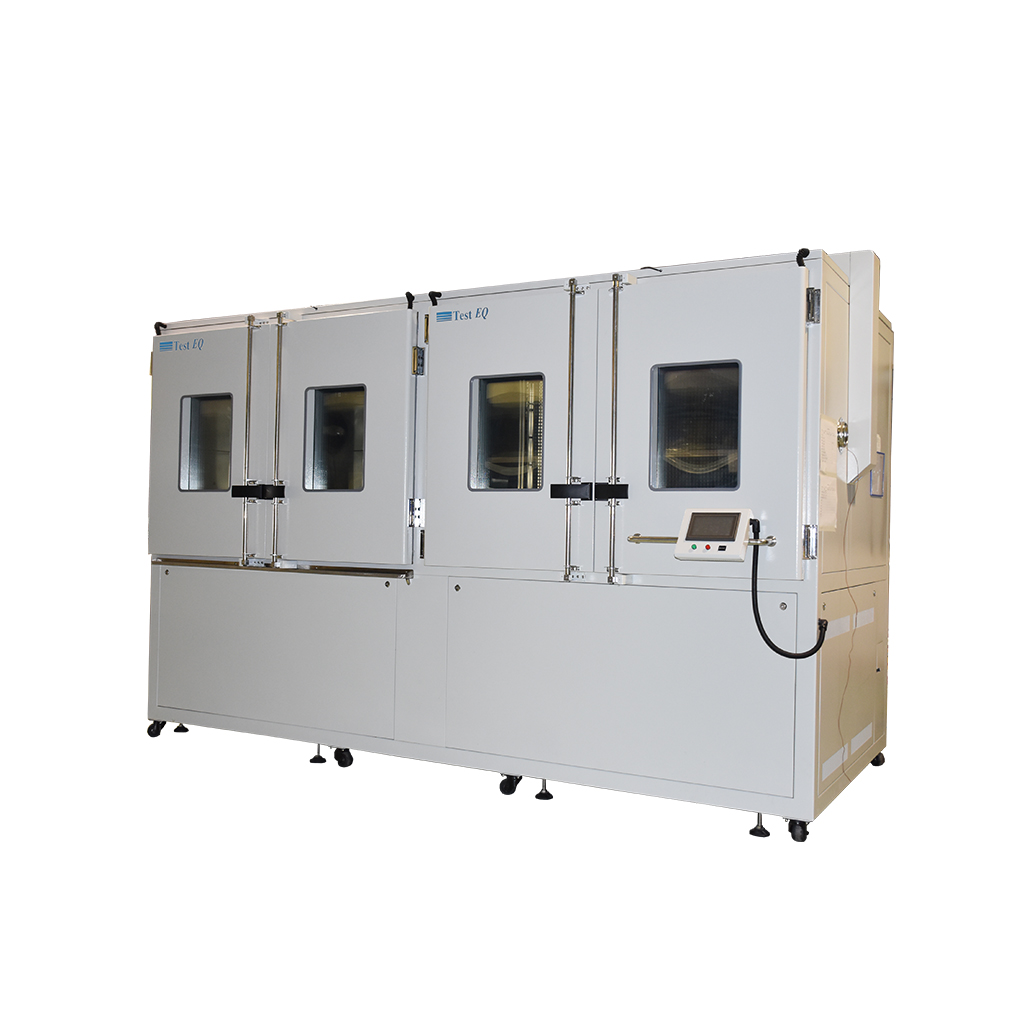

1.Integrated Structure: TIG seamless welding for internal construction with an aesthetically sleek design; lever-powered door lock mechanism.

2.Intelligent Control System: Chinese color LCD touchscreen human-machine interface (HMI) + high-performance programmable logic controller (PLC), paired with TEST EQ’s proprietary software for automated, intelligent, and user-friendly operation.

3.Control Modes: Constant operation and programmable operation.

4.Energy Efficiency: TEST EQ’s patented "Cold and heat balance technology ” reduces energy consumption by over 30% during low-temperature constant conditions.

5.Reliable Components: Internationally renowned compressors and critical parts ensure long-term reliability; eco-friendly refrigerants comply with global environmental protocols.

6.Humidification System: TEST EQ’s patented humidification technology (for humidity testing).

7.Pressure Resistance: Internal or external pressure-resistant configurations.

8.Vacuum System: Equipped with world-class brands Leybold or Nash.

9.Connectivity: RJ45 communication interface and remote control system (supports Modbus/OPC data transmission protocols).

10.Customizable Aesthetics: Electrostatic powder-coated exterior in "TEST EQ White" and door panel in "TEST EQ Blue."

11.Anti-Condensation Function (Optional): TEST EQ’s patented cold-well adsorption technology.

Standards

GB10590-89 Low-temp/low-pressure testing

GB15091-89 High-temp/low-pressure testing

GB11159-89 General low-pressure testing

GB/T2423.25-1992 Temp/pressure combined testing

MIL-STD-810H Military equipment environmental engineering

RTCA DO-160G Avionics equipment testing

IEC 60068-2-41 Combined temp/low-pressure testing

IEC 60068-2-13 High-temp/low-pressure testing

ASTM E595-07 Outgassing under thermal vacuum

ISO 7137:1995Aircraft environmental conditions