Features

1. Precision Engineering & Durability

• Seamless Construction: TIG-welded stainless steel interior with anti-corrosion coating; lever-assisted door locking system for airtight sealing.

• Pressure & Vacuum Capabilities: Configurable for internal/external pressure resistance (up to 2 atm) and vacuum simulation (using Leybold or Nash systems).

2. Smart Control & Automation

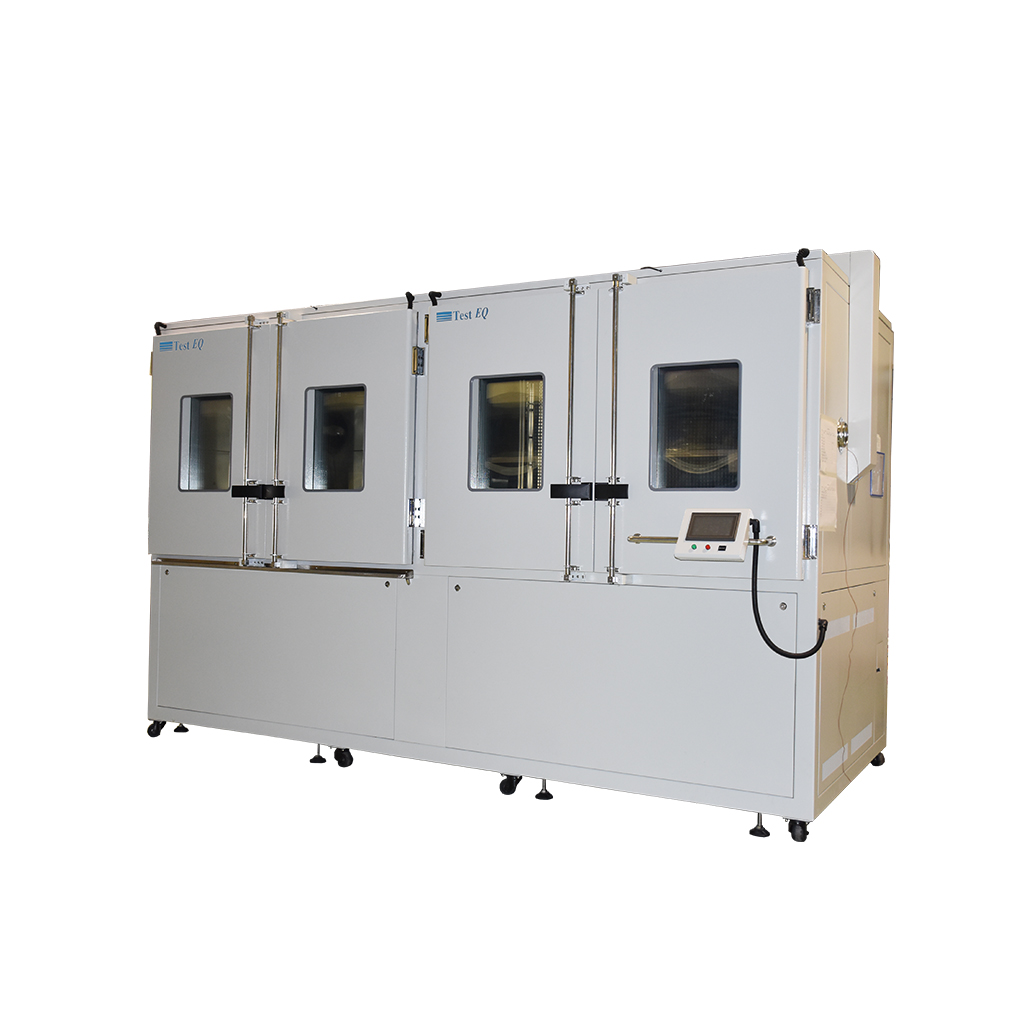

• AI-Driven Interface: 10" color touchscreen HMI with multi-language , paired with PLC and TEST EQ Pro Software for real-time data logging, predictive maintenance alerts, and remote monitoring via Modbus/OPC protocols.

• Flexible Programming: Supports constant conditions, cyclic stress profiles, and custom sequences (1,000+ programmable steps).

3. Energy Efficiency & Sustainability

• Cold and heat balance technology: Patented refrigeration system reduces energy consumption by 30% during low-temperature stabilization (-70°C to +150°C range).

• Eco-Certified Components: R290/R744 refrigerants and LEED-compliant humidification systems minimize carbon footprint.

4. Advanced Humidity Control

• Steam Injection Technology: Achieves 10%–98% RH accuracy with rapid humidification/dehumidification cycles (<3% deviation).

• Anti-Condensation Option: Cold-trap adsorption prevents frost buildup during rapid temperature transitions.

5. Global Compliance & Customization

• Standards Certified: IEC 60068, MIL-STD-810, DO-160G, GB/T, and GJB series for multinational regulatory alignment.

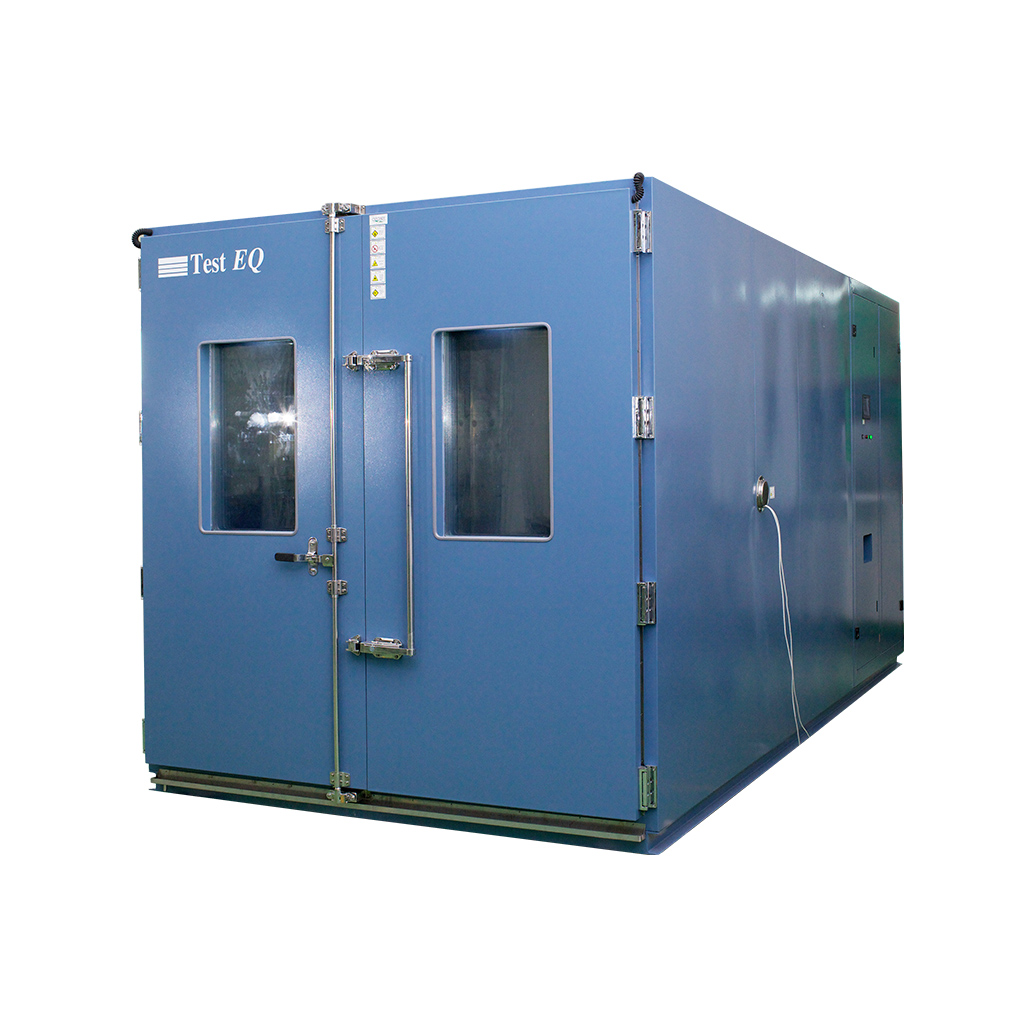

• Aesthetic Flexibility: Powder-coated exteriors in TEST EQ White/Blue or client-branded colors; modular designs for lab integration.