Superior Performance, Lower Total Cost of Ownership with thermal shock chamber:

Energy Intelligence: TestEQ cascade refrigeration and counter-flow heat exchange technology reduce energy consumption by up to 30% compared to conventional designs.

Maintenance Simplified: Smart systems with pressure monitoring and modular components guide technicians, cutting maintenance time by 40%. Predictive alerts prevent costly repairs.

Calculate Your Savings: Discover your potential ROI. Use our interactive TCO Calculator to see how lower energy cost and reduced downtime translate directly to your bottom line.

Download the Semiconductor Testing Whitepaper

Feature

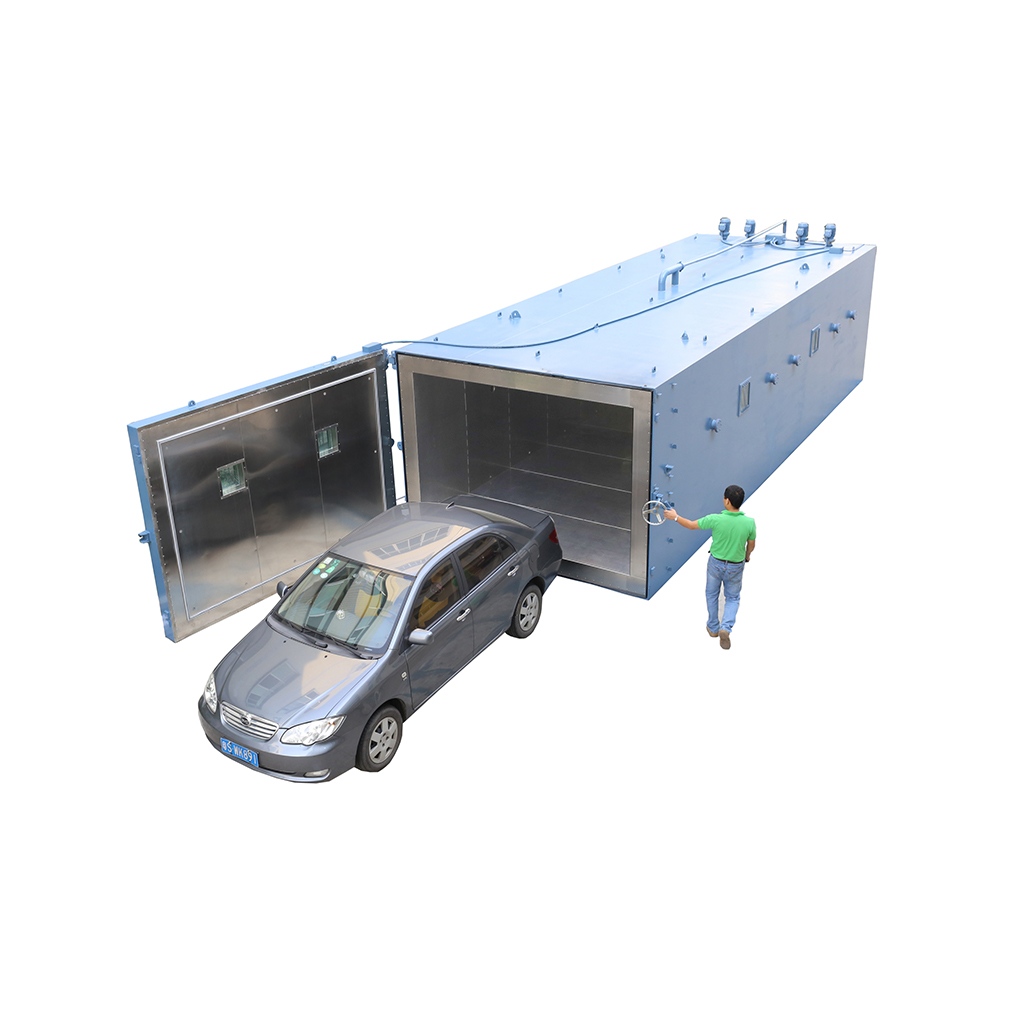

1.Integral structure,the internal overall TIG seamless welding, beautiful appearance; Door lock device adopts lever power opening mechanism.

2.The use of Chinese color LCD touch man-machine interface + high-performance programmable controller (PLC), with TESTEQ test box independently developed special software, with automatic, intelligent, human control and other characteristics.

3.TESTEQ patent "Cold and heat balance technology",low temperature constant temperature season can be more than 30%.

4.Control mode: constant operation mode, program operation mode.

5.Refrigeration compressor and key accessories are selected international and domestic well-known brands, long-term and reliable operation; Environmentally friendly refrigerant, in line with the requirements of international environmental protection conventions.

6.Two-box type (vertical/horizontal) : independent high greenhouse and low greenhouse, the test sample through the basket up and down (or around) action conversion, to achieve the impact test in the high temperature, low temperature area, temperature recovery time is short, temperature change speed, compact structure, small volume.

7.The one-box test sample has been static, its temperature conversion through the pneumatic system to open (close) different air doors to achieve, easy to carry out online testing, reduce the mechanical impact on the test sample. Room temperature exposure test can be performed.

8.Configure RJ45 communication interface and remote control system (open data transmission protocol supports Modbus/OPC).

9.Surface electrostatic powder spraying; Box color"TESTEQ White", Controller panel color "TESTEQ Blue".