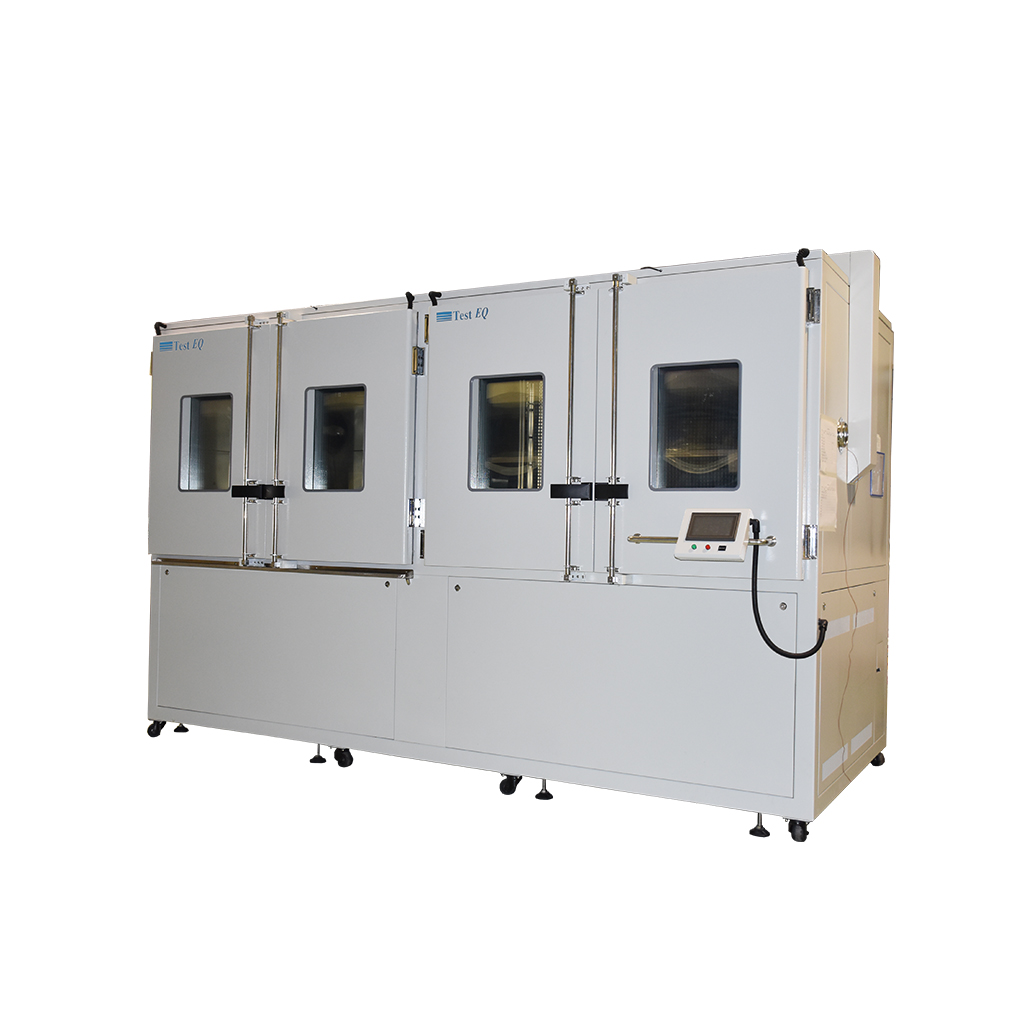

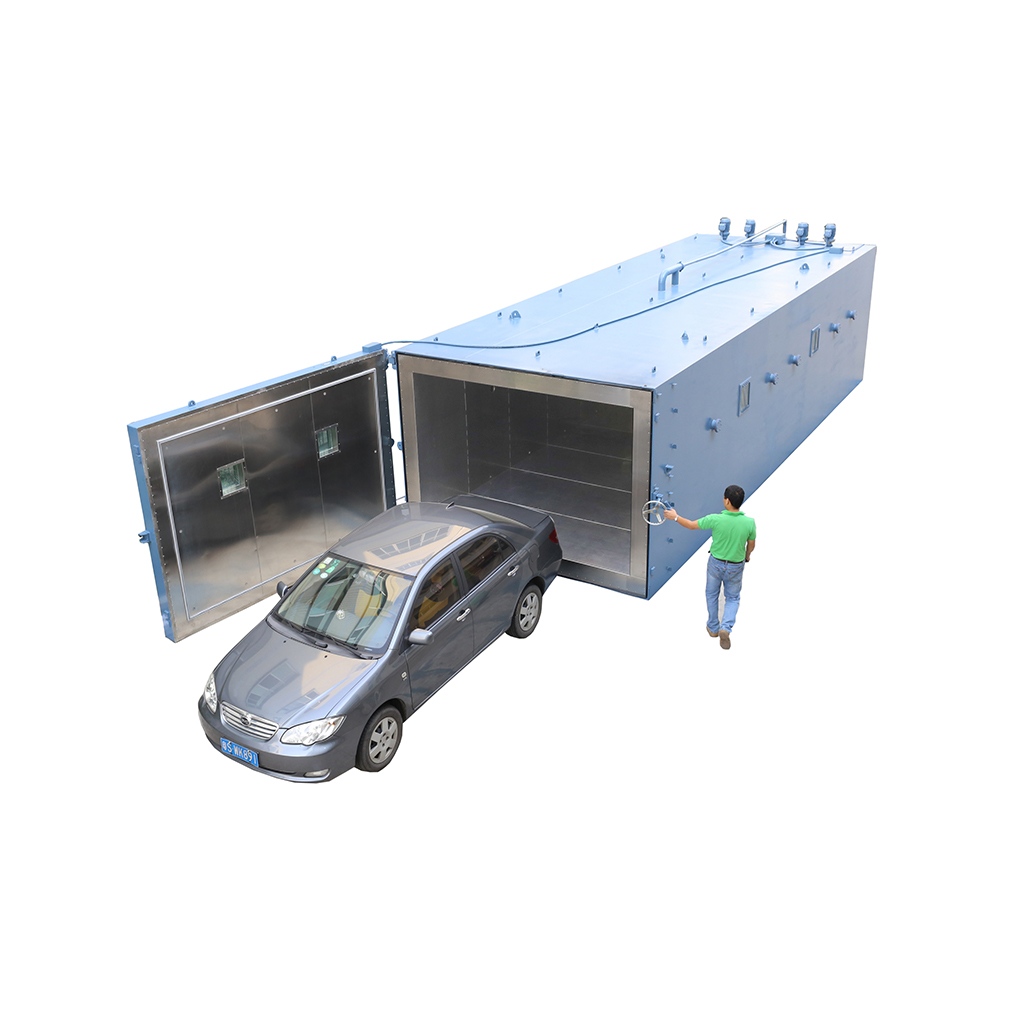

Features

1.Precision Gas Dosing

•Delivers exact concentrations of corrosive gases (e.g., H₂S, SO₂, Cl₂ with N₂ carrier gas; NO₂ with synthetic air) for repeatable test conditions.

•Supports simultaneous dosing of up to four gases, enabling multi-pollutant interaction studies.

2.Observability & Safety

•Acrylic (PMMA) viewing window allows real-time monitoring of specimens without compromising test integrity.

•Pressure monitoring system and gas sampling port ensure operator safety and compliance with industrial hygiene standards.

3.Advanced Environmental Control

•Integrated air exchange module maintains consistent gas distribution and replicates dynamic atmospheric conditions.

4.Standards Compliance

•Certified for IEC 60068-2-60, 60068-2-42/43, ISO 21207, and other global protocols, guaranteeing internationally recognized results.

Standards Supported

The AirEvent Chamber adheres to rigorous testing frameworks, including:

•IEC 60068-2-60: Corrosion testing with mixed flowing gases.

•IEC 60068-2-42/43: Sulfur dioxide and hydrogen sulfide exposure tests.

•ISO 21207: Accelerated corrosion via combined environmental stressors.

Why Choose AirEvent?

•Data-Driven Lifespan Prediction: Quantify degradation rates to optimize material selection and warranty periods.

•Scalable Testing: Configure gas combinations and concentrations to mirror region-specific or industry-tailored conditions.

•Future-Proof Design: Compatible with emerging pollutant regulations and next-gen material innovations.

Elevate your quality assurance strategy with the AirEvent Chamber—engineered to expose weaknesses before they reach the market.

Contact our team to customize your testing protocol today.