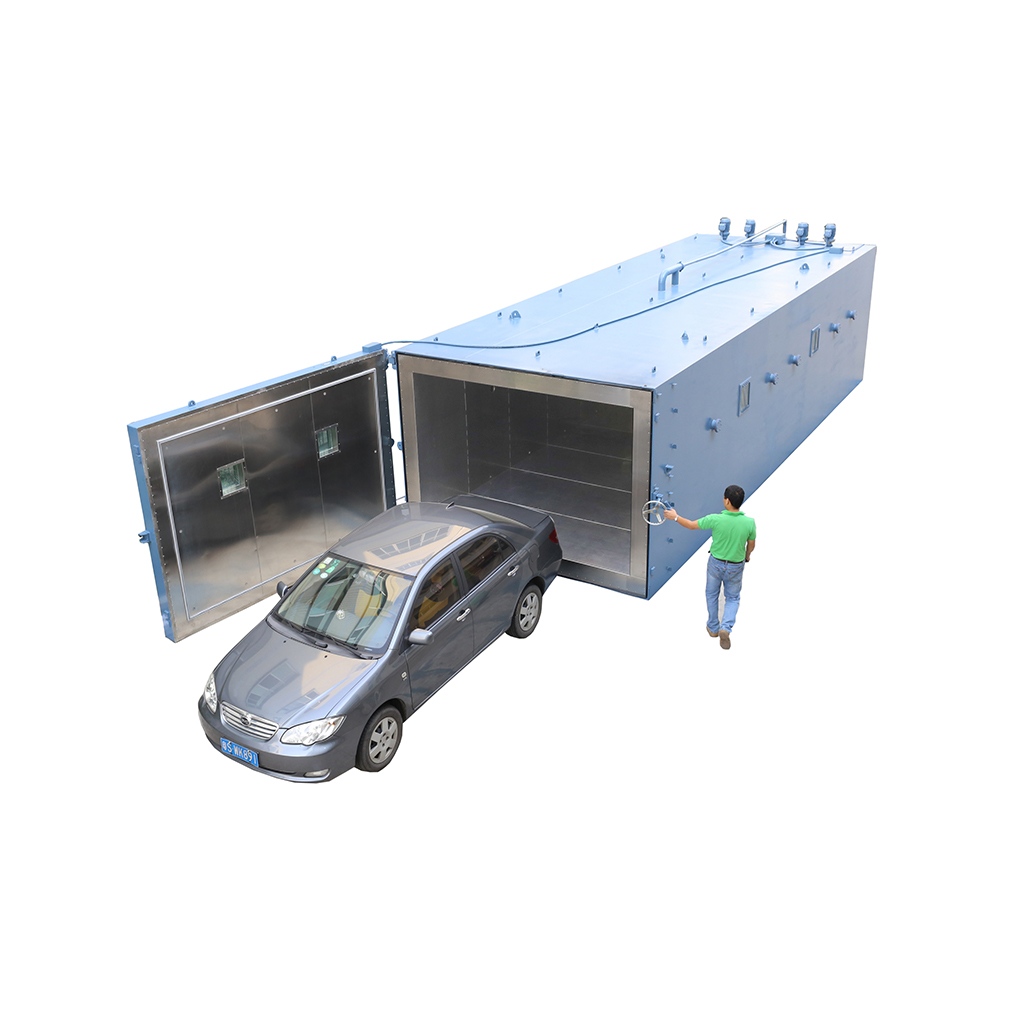

Safety Features

1.Unmatched Energy Efficiency – 30% Reduction in Power Consumption:

The Cold-Hot Balance technology isn't just about precision; it's about performance. We directly address the high cost of operation,

a major pain point for our clients. By slashing energy use by 30%, the TESTEQ 3.0 Series delivers a faster return on investment and a significantly reduced operational footprint.

2.Intelligent Control System with Cold-Hot Balance Technology:

Our pioneering system actively manages energy distribution within the chamber.

Unlike conventional systems that simply fight the heating with cooling (and vice versa), it intelligently recovers and repurposes energy.

This eliminates thermal conflict, ensures exceptional temperature uniformity (±0.5°C), and provides massive energy savings.

3..Battery-Specific Thermal Management:

•Dual-compressor cascade cooling (-40°C stability) and ceramic heaters for rapid high-temperature recovery.

4.Precision Electrochemical Control:

•Integrated battery cyclers with CAN/Modbus protocols, supporting SOP (State of Power), SOH (State of Health), and DCR (Direct Current Resistance) monitoring.

5.Safety-Centric Design-meet Hazard level:

• chambers are designed with Fire-resistant stainless steel interior, fire suppression,nitrogen purge system, and emergency power cutoff for thermal runaway prevention .

6.Data Acquisition & AI Analytics:

•Real-time logging of voltage, current, temperature, and pressure via LabVIEW/Python APIs. AI-driven anomaly detection reduces test cycles by 30%.

7.Energy Efficiency and Energy storage:

•Heat recovery during discharge cycles cuts energy use by 25% (ISO 50001 compliant).

Standards Compliance

1.Global Safety:

•UL 2054:2025 (Household Batteries), IEC 62133-3:2024 (lithium ion batteries systems).

2.Automotive:

•SAE J2464 (Abuse Testing), GB/T 31485 (EV(Electric vehichles) Battery Safety).

3.Industrial:

•ISO 12405-4 (Performance Testing), UN 38.3 (Transportation) .

4.Sustainability:

•EU Battery Regulation 2025/07 (Carbon Footprint Tracking), REACH SVHC compliance.