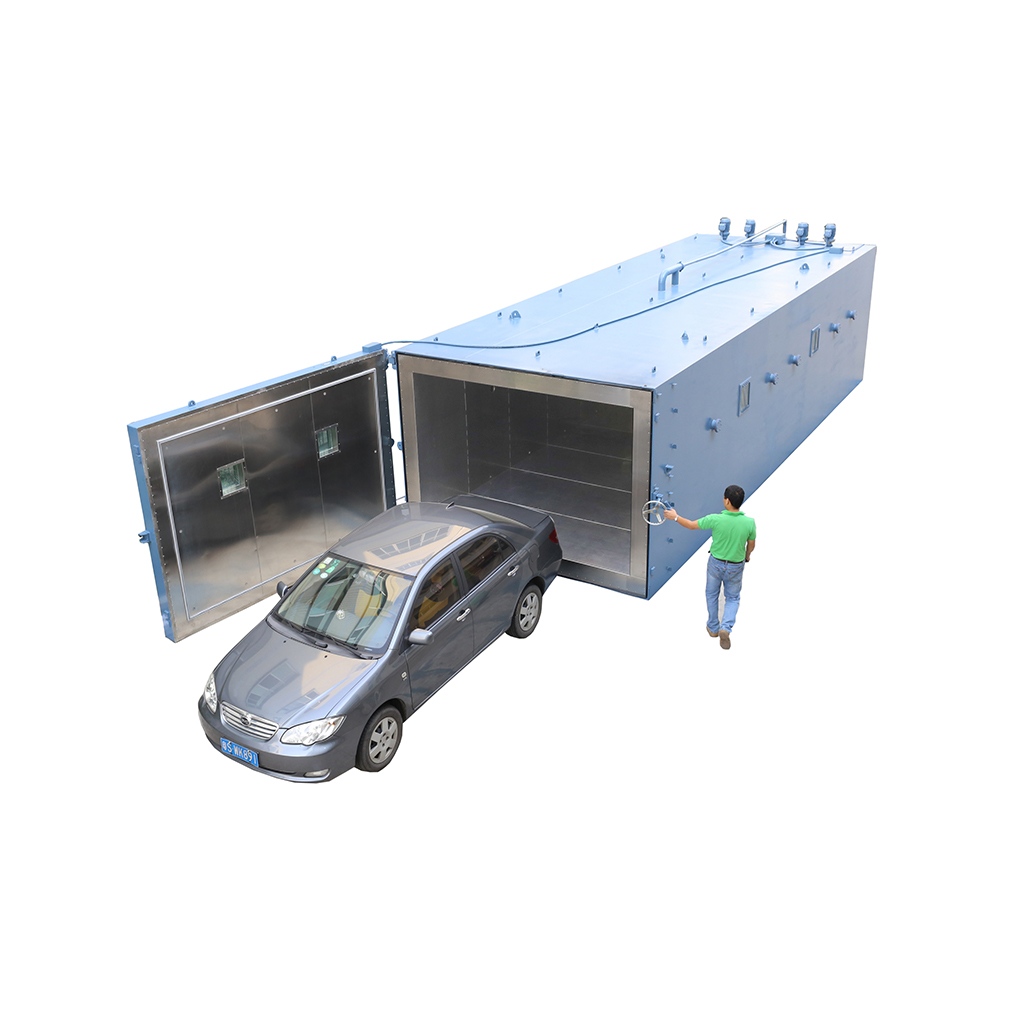

A fully automatic thermal vacuum cleaning equipment specially designed for components of lithography machines and mask plates. Through a high-temperature and low-pressure environment and non-contact dry cleaning technology, it can thoroughly remove nano-level contaminants (such as organic residues and particles), meeting the strict requirements for ultra-clean surfaces in semiconductor manufacturing, flat panel display, and integrated circuit fields. It supports multi-scenario cleaning of wafers, optical lenses, vacuum chambers, etc.

Patent Number: CN202510795397.6

Feature:

✅ Unmatched Cleaning Performance – Removes Sn residues (EUV), hydrocarbons, oxides, and sub-100nm particles for defect-free production.

✅ Smart Process Control – Automated recipes with pressure/temperature profiling for repeatable results.

✅ Multi-Technology Integration – Combine thermal, plasma, and ultrasonic cleaning in one system.

✅ Non-Destructive Cleaning – Gentle on EUV multilayer optics, reticles, and delicate sensors.

✅ SEMI & ISO-Compliant – Meets ISO Class 1 cleanliness standards with full traceability.

✅ 24/7 Production Ready – Designed for high-throughput semiconductor fabs with minimal downtime.

Critical Applications

1. EUV Lithography Systems

Mirror & Collector Optics Cleaning – Eliminates Sn droplets and carbon buildup.

Reticle & Pellicle Maintenance – Ensures zero mask defects.

Vacuum Chamber Conditioning – Prevents contamination in EUV source modules.

2. DUV Lithography & Advanced Packaging

Lens & Prism Decontamination – Stops haze formation.

Wafer Chuck & Stage Recovery – Restores optimal electrostatic clamping.

3. R&D & Failure Analysis

Prototype Surface Prep – Clean surfaces for SEM, TEM, XPS analysis.

Why Choose TESTEQ?

✅ Higher Yield – Reduces particle-related defects by >90% (verified in leading fabs).

✅ Longer Component Life – Extends service intervals for EUV nozzles, DUV lenses, and chucks.

✅ Faster ROI – Minimizes manual cleaning and requalification time.

✅ Custom Solutions – Tailored configurations for your specific components.