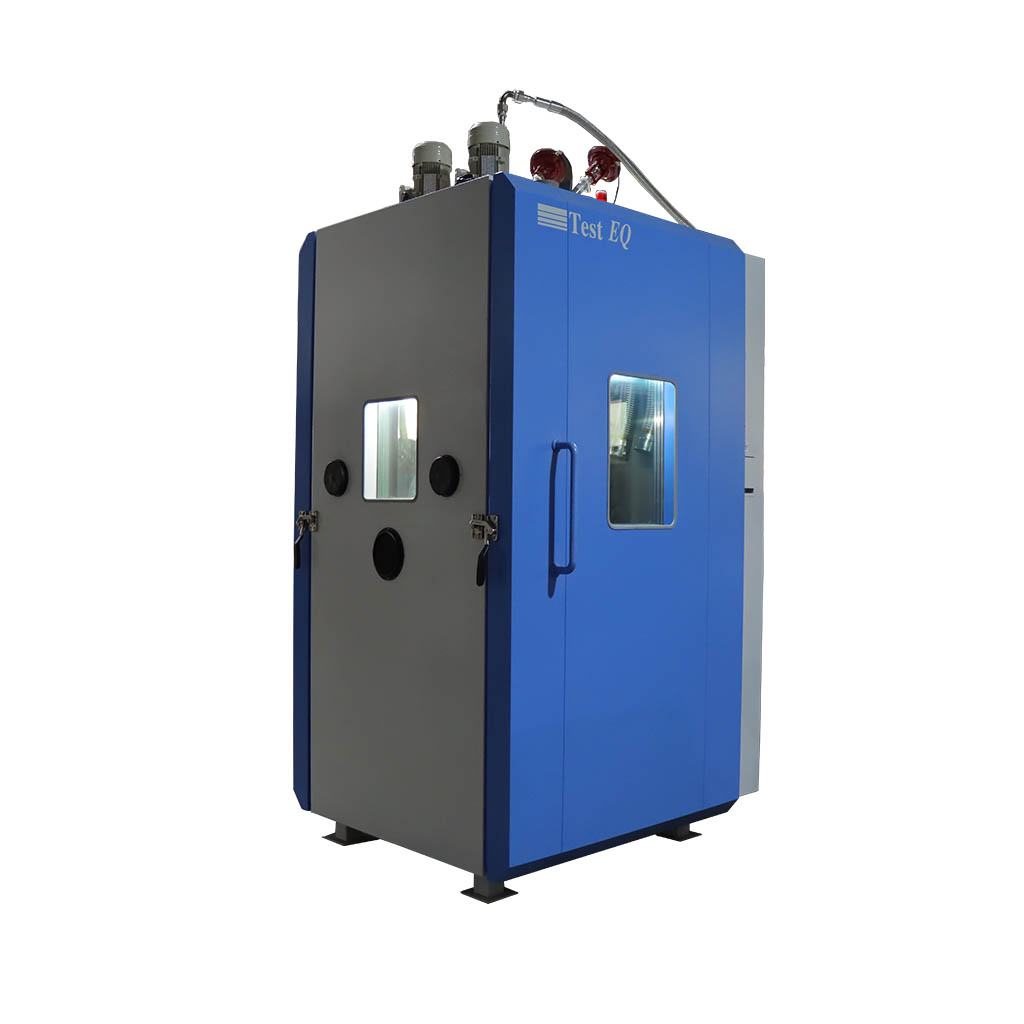

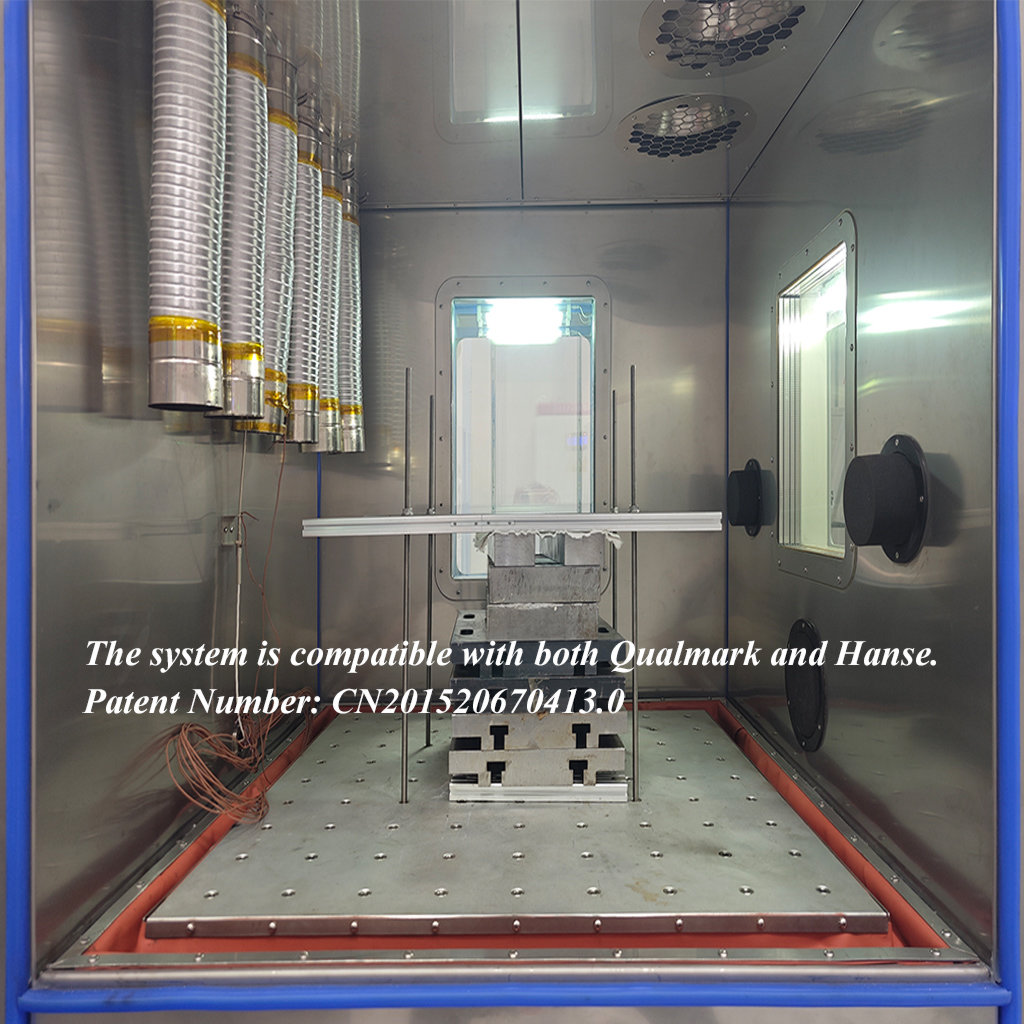

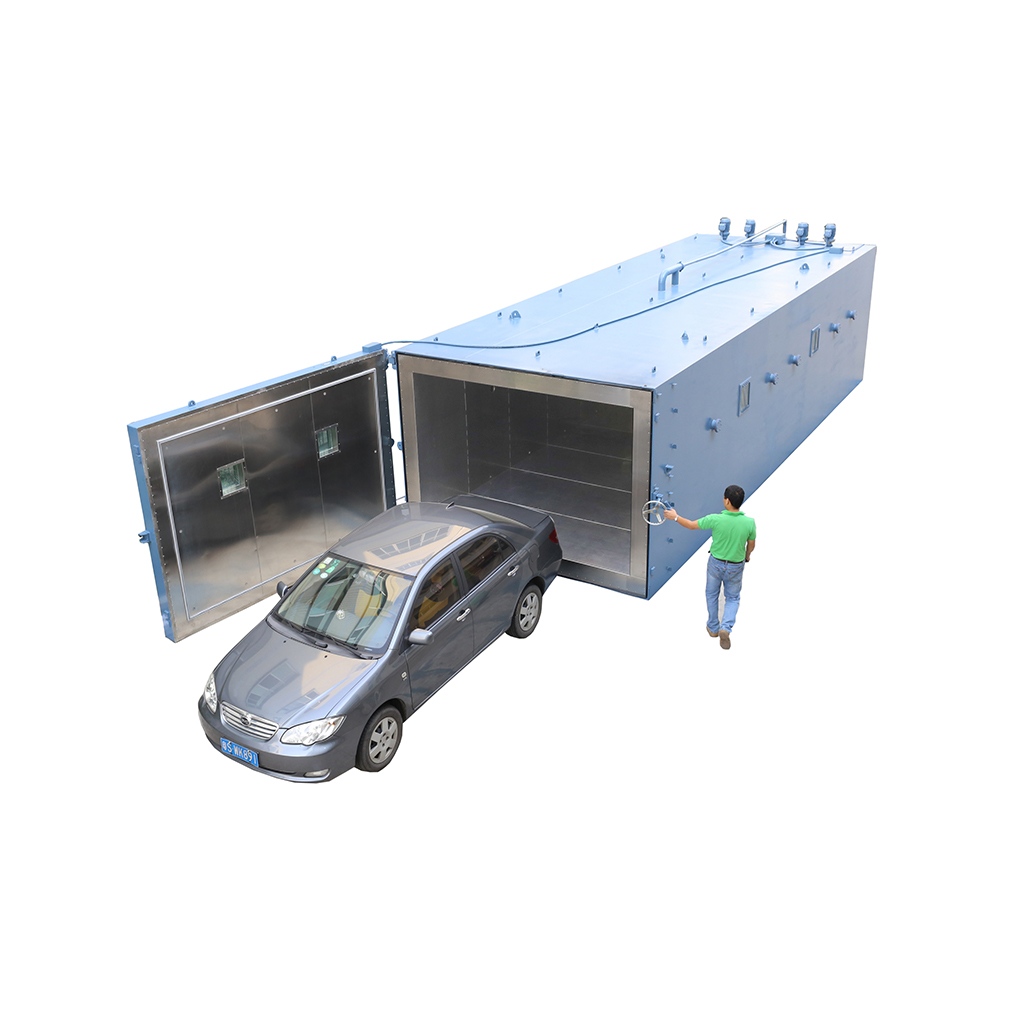

Features of product development

· Rapid Temperature Cycling: Achieves rates up to 100°C/min for accelerated stress screening hass.

· Multi-Axis Vibration: Combines pneumatic (6-DOF) and electrodynamic vibration for multi-stress accelerated life testing halt simulations.

· Precision Control: halt process ±0.5°C temperature uniformity and real-time monitoring.

· Customizable Profiles: Supports stress levels user-defined stress protocols (step-stress, dwell times).

· Durability: Robust construction with corrosion-resistant materials

Testing Standards

1. Military Standards (MIL-STD)

MIL-STD-810

Title: Environmental Engineering Considerations and Laboratory Tests

Applicability: Environmental adaptability of military equipment (traditional environmental testing, not a direct HALT/HASS standard but may serve as a reference).

Note: HALT/HASS accelerated stress conditions typically exceed this standard’s conventional temperature change rates (5–15°C/min).

MIL-STD-883

Title: Test Methods and Procedures for Microelectronic Devices

Applicability: Reliability testing of electronic components; some methods (e.g., temperature cycling) may be combined with HALT/HASS.

MIL-STD-202

Title: Test Methods for Electronic and Electrical Component Parts

Applicability: Environmental stress screening (ESS) for electronic components, partially related to HASS.

MIL-STD-750

Title: Test Methods for Semiconductor Devices

Applicability: Reliability testing of discrete semiconductor devices.

2. Aerospace & Satellite Standards

RTCA DO-160

Title: Environmental Conditions and Test Procedures for Airborne Equipment

Applicability: Environmental testing for avionics (traditional tests; HALT/HASS used for accelerated R&D validation).

NASA GSFC-STD-7000

Title: Environmental Verification Standard

Applicability: Satellite and spacecraft components; recommends HALT as a design validation tool.

ECSS-Q-ST-30 (European Cooperation for Space Standardization)

Series: Includes ECSS-Q-ST-30-02 (Reliability Testing), supporting accelerated stress methods.

AIAA S-114

Title: Guide for Reliability Testing of Space Systems

Applicability: Recommends HALT/HASS for spacecraft component screening.

3. Automotive Industry Standards

IEC 60068 (International Electrotechnical Commission)

Series: e.g., IEC 60068-2-14 (Temperature Change Testing), referenced by some automakers for HALT.

ISO 16750

Title: Road Vehicles — Environmental Conditions and Testing for Electrical and Electronic Equipment

Applicability: Reliability testing for automotive electronics; HALT used for early-stage design validation.

SAE J1211

Title: Guidelines for Environmental Testing of Automotive Electronic Systems

Applicability: Recommends HALT/HASS to enhance reliability.

OEM-Specific Standards:

Ford (WARR), GM (GMW 3172), Volkswagen (TL 82066) require HALT/HASS during R&D.

4. Electronics Industry Standards

IPC-9592

Title: Accelerated Reliability Testing of High-Reliability Electronic Devices

Applicability: Consumer/industrial electronics; defines HALT/HASS processes.

JEDEC JESD22

Series: e.g., JESD22-A104 (Temperature Cycling), complementary to HALT/HASS.

Telcordia GR-468-CORE

Title: Generic Reliability Assurance Requirements for Optoelectronic Devices

Applicability: Recommends HALT for early failure detection in telecom equipment.

IEC 60749

Title: Semiconductor Devices — Mechanical and Climatic Test Methods

Applicability: Reliability testing for semiconductors.

5. General International Standards

IEC 60068-3-1

Title: Environmental Testing — Guidance for Temperature Testing

Applicability: Provides theoretical basis for temperature change rates (HALT/HASS equipment selection reference).

IEEE 1624

Title: Standard for Reliability Prediction for Electronic Systems

Applicability: Recommends HALT as a reliability design tool.

Key Notes:

Military/Aerospace: Focuses on extreme environmental adaptability, though HALT/HASS is often a supplemental method (non-mandatory).

Automotive/Electronics: More standards directly cite HALT/HASS (e.g., IPC-9592, SAE J1211), with OEMs often defining stricter criteria.

Equipment Selection: Parameters (e.g., temperature ramp rates, vibration profiles) must align with specific standards (e.g., IPC-9592’s rapid thermal cycling requirements).

For practical applications, align testing protocols with industry-specific standards and customer requirements.