Advanced Constant Temperature and Humidity Chambers for Aerospace and Satellite Testing Excellence

In the high-stakes realm of aerospace and satellite engineering, precise environmental simulation is not just a requirement—it's a lifeline.

Our state-of-the-art constant temperature and humidity chambers deliver unparalleled reliability for testing critical components, from satellite payloads to avionics systems.

Engineered to meet rigorous standards like MIL-STD-810 and DO-160, these chambers ensure your missions withstand extreme conditions, reducing failure risks by up to 99%.

With over 2 decades of innovation, we empower leaders in aerospace—think NASA, ESA, and commercial space pioneers—to achieve flawless performance in every launch.

Discover how our humidity control technology transforms testing from a challenge into a competitive advantage.

I. Core Product Features: Precision Humidity and Temperature Control

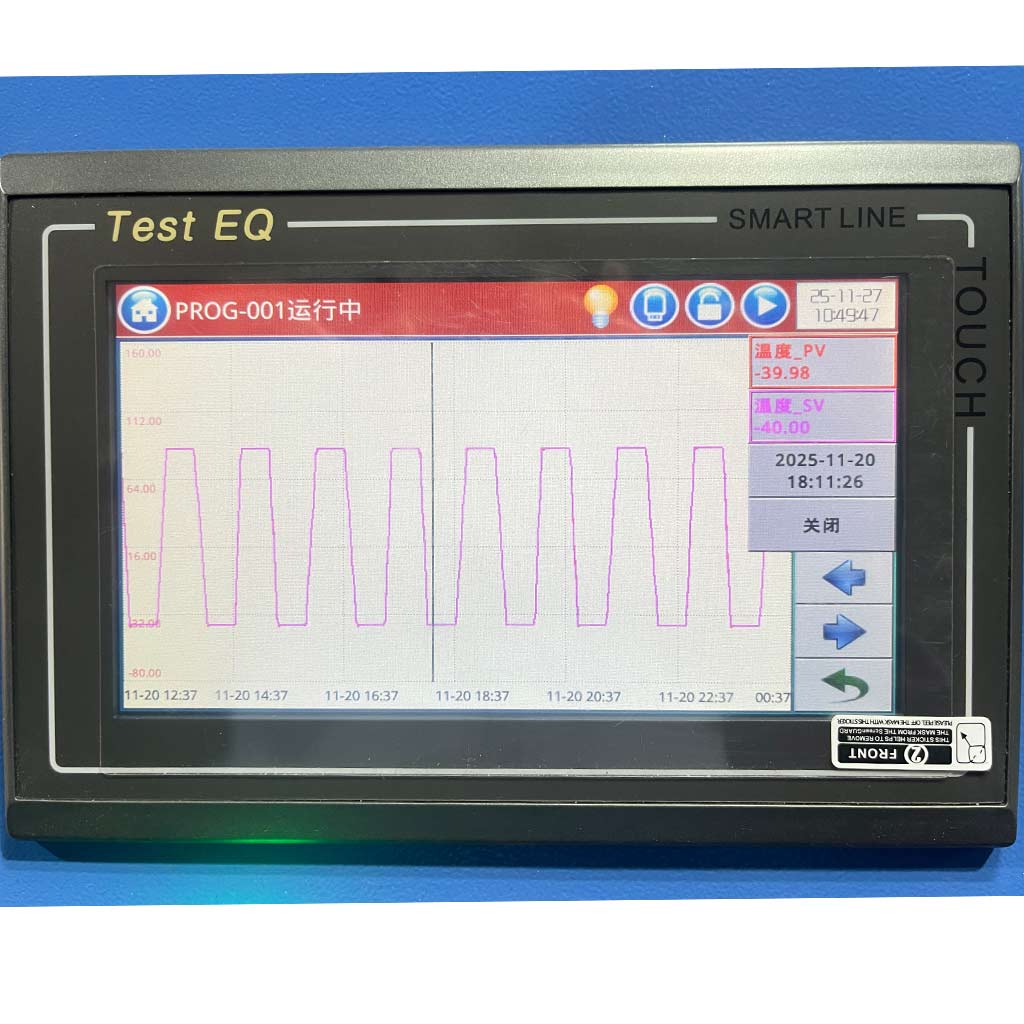

At the heart of our solution lies advanced engineering for seamless constant temperature and humidity control, designed to simulate everything from Earth's atmosphere to the vacuum of space. Unlike standard chambers, our models integrate smart sensors and AI-driven algorithms to maintain exact conditions, ensuring consistent results for humidity chamber testing.

Ultra-Stable Environment: Our constant temperature humidity chamber achieves fluctuations of just ±0.1°C and ±1% RH, critical for satellite thermal management. This stability prevents condensation or drying that could compromise sensitive electronics.

Broad Operational Range: Catering to diverse needs, we offer high humidity chamber capabilities (up to 98% RH for tropical simulations) and low humidity chamber functions (down to 10% RH for desert or space vacuum analogs). This flexibility supports everything from component stress tests to full-system validations.

Intelligent Control Systems: Features like real-time temperature humidity control chamber monitoring and automated adjustments via cloud-based software. This ensures controlled humidity chamber operations without manual intervention, saving up to 30% in testing time.

By incorporating thermal humidity chamber technology, we address common pain points like drift or hysteresis, making our equipment ideal for long-duration missions.

II. Specialized Chamber Types for Demanding Applications

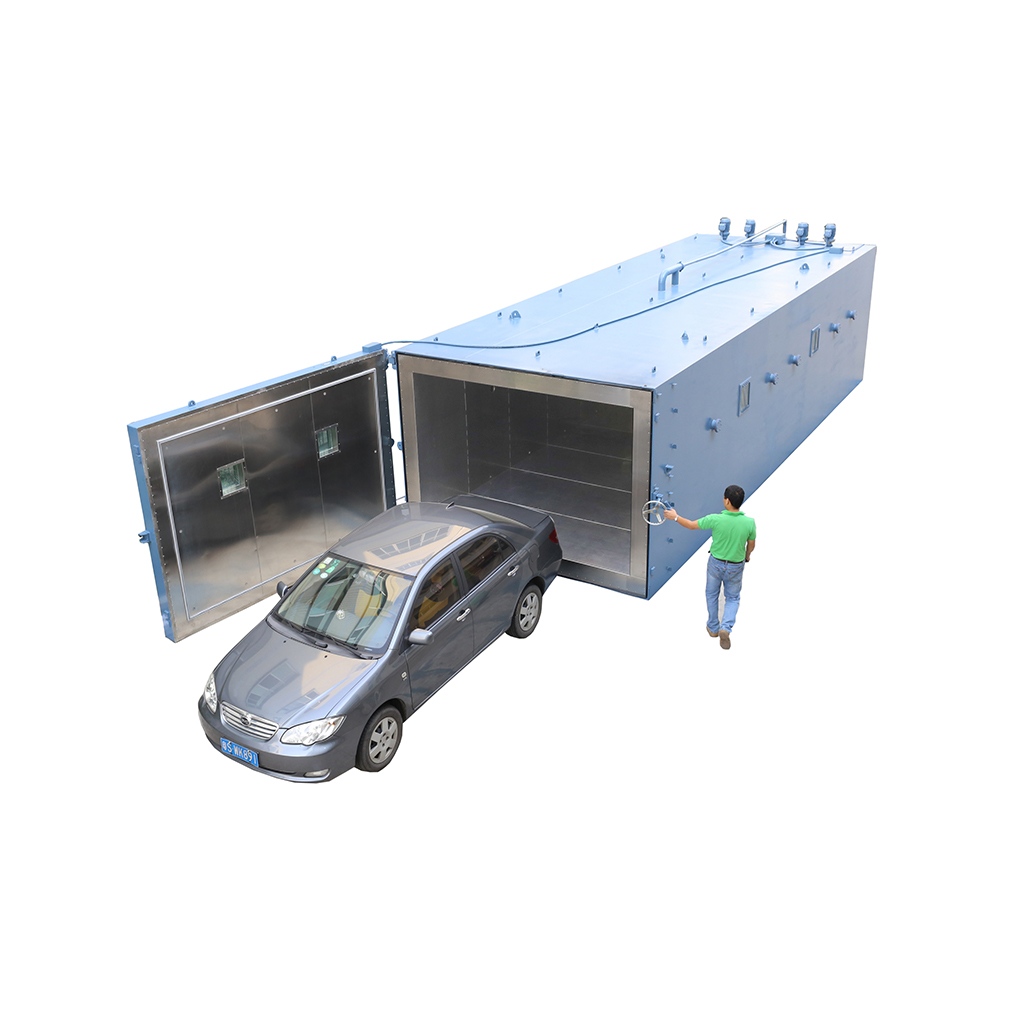

To meet the unique demands of aerospace, we provide tailored solutions, including walk-in units for large-scale assemblies and compact models for benchtop precision.

Walk-In and Benchtop Options: Our walk in humidity chamber accommodates full satellite mock-ups, enabling end-to-end environmental chamber humidity testing in a single, scalable space. Conversely, smaller constant humidity chamber units target subsystem checks, such as sensor calibrations.

Enhanced Testing Capabilities: As a leader in humidity environmental test chambers, we support combined stresses—e.g., temperature & humidity chamber cycles that replicate re-entry heat and moisture. This holistic approach, including temperature and humidity testing, validates resilience against real-world anomalies like solar radiation or atmospheric ingress.

These designs stem from decades of field data, ensuring compliance with ASTM E595 and other benchmarks for outgassing and contamination control.

III. Aerospace and Satellite Testing Applications

Specifically engineered for the aerospace sector, our chambers excel in scenarios where failure is not an option. Humidity environmental chamber systems are pivotal for:

Satellite Component Validation: Simulate orbital humidity variations to test solar panels, batteries, and communication systems. For instance, humidity chamber testing under vacuum-like conditions ensures hardware survives launch vibrations and space exposure.

Aircraft and Avionics Certification: Conduct temperature and humidity testing on cockpit displays or navigation systems, using constant temperature and humidity test chamber protocols to meet FAA and EASA mandates. Case studies show our chambers cut certification timelines by 40%, with zero non-conformities in audits.

R&D Innovation: Support next-gen projects like Mars rovers or low-Earth orbit satellites. Our environmental chamber humidity features enable rapid prototyping, where controlled humidity chamber settings mimic Martian atmospheres or high-altitude flights.

This application focus reduces costs (e.g., 50% lower rework rates) and enhances safety, as demonstrated in partnerships with top-tier aerospace firms.

IV. Technical Advantages and Industry Compliance

Beyond basic functions, our chambers offer unmatched reliability through cutting-edge features and global standards adherence.

Robust Construction: Built with aerospace-grade materials (e.g., stainless steel interiors), our temperature humidity control chamber resists corrosion and ensures longevity, even in high-salt or high-pollution environments.

Data-Driven Insights: Integrated with IoT for real-time humidity chamber testing analytics, providing reports on performance trends and predictive maintenance. This aligns with Industry 4.0, turning test data into actionable intelligence.

Regulatory Excellence: Full compliance with DO-160 Section 6 (humidity) and ISO 17025, supported by calibration certificates. Our constant temperature and humidity chamber solutions are trusted for mission-critical programs, from GPS satellites to crewed spacecraft.

Conclusion: Elevate Your Testing with Unrivaled Precision

In an era where aerospace innovation hinges on flawless environmental simulation, our constant temperature humidity chambers stand as your ultimate partner.

By integrating all 16 core keywords—from high humidity chamber to humidity environmental test chambers—this solution delivers not just equipment,

but peace of mind. Experience reduced risks, accelerated time-to-market, and unwavering accuracy for satellite and aerospace endeavors.

Ready to transform your testing protocols?

Contact our experts today(Check Here)for a customized demo and see why industry leaders rely on us for every frontier.