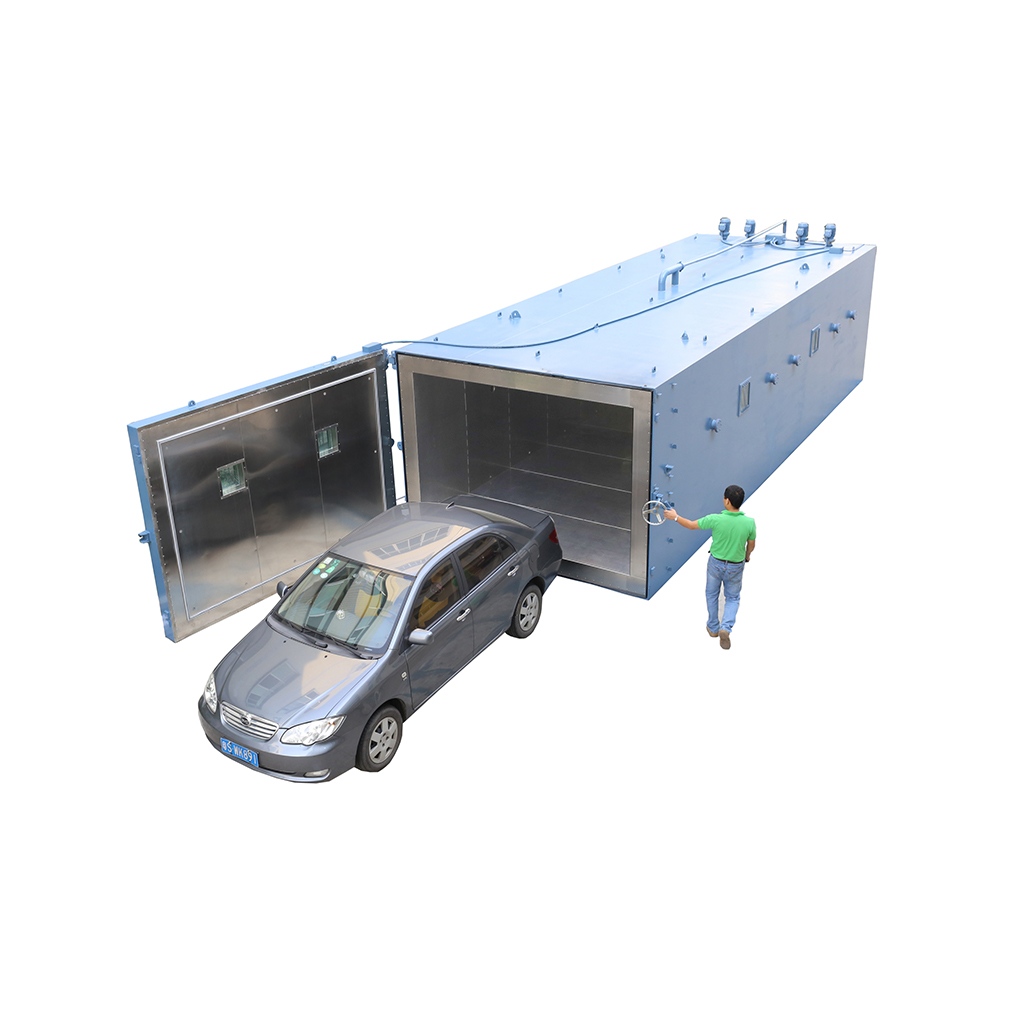

1.Reliable Thermal Shock Testing for Automotive Excellence

Ensure automotive component durability with our advanced ice water shock test chamber. Designed to simulate sudden temperature changes—such as hot engine parts hitting icy road spray—this system rigorously evaluates engines, brake valves, ECUs, and battery packs for thermal resilience and sealing integrity. Meet ISO and OEM standards with precision-controlled testing that mirrors real-world winter driving conditions.

2. Validate Electronics in Extreme Environments

From smartphones to industrial control units, electronic devices must withstand rapid temperature shifts and moisture exposure. Our ice water immersion tester replicates harsh scenarios like rain-soaked operation or snowmelt contact, verifying waterproof performance and long-term reliability of PCBs, connectors, sensors, and outdoor enclosures used in telecom, consumer tech, and transportation sectors.

3. Aerospace-Grade Thermal Shock Solutions

Certify aerospace components under MIL-STD-810G and DO-160 compliance with high-fidelity ice water shock testing. Test aircraft engine inlets, avionics housings, and re-entry vehicle seals against extreme thermal cycling between sub-zero altitudes and ground temperatures. Our chambers deliver unmatched accuracy for mission-critical reliability validation in aviation and space exploration systems.

4. Battery & EV Component Resilience Under Cold Stress

Accelerate innovation in electric mobility with precise low-temperature impact assessment. Our thermal shock chamber tests EV battery modules, power electronics, and charging infrastructure under simulated ice-water splash conditions—detecting seal failures, internal resistance spikes, and capacity degradation before deployment. Essential for ensuring safety and longevity in next-gen energy storage systems.

5. Sealing Performance Validation for Connectors & Cables

Protect signal integrity and prevent corrosion in automotive and industrial wiring systems. This ice water shock tester assesses the hermetic sealing of electrical connectors, harnesses, and junction boxes during abrupt thermal transitions—critical for autonomous vehicles, robotics, and outdoor communication networks exposed to freezing rain and thaw cycles.

6. Material Durability Testing for Plastics & Elastomers

Evaluate the long-term behavior of rubber gaskets, polymer seals, and composite materials under repeated thermal stress. Our chamber simulates decades of environmental aging in weeks by cycling samples between elevated operating temps and ice-cold immersion—revealing cracking, shrinkage, and loss of elasticity early in R&D or quality assurance workflows.

Your R&D Deserves Better Data – Validate with Our Tools

5,000+ Industrial Clients Can’t Be Wrong "Test Us Today" TestEQ sales team will reply you within today for your scheme.